Ensuring potency, avoiding financial loss, and providing a compliant product matching legal and consumer criteria all depend on controlling cannabis quality following harvest. If handled carelessly, post-harvest bud rot, brought on mostly by microbial deterioration, can ruin whole batches. This guide provides modern, practical advice on preventing post-harvest rot in cannabis through environmental control, cleanliness, and best handling techniques.

Knowing the Risk of Cannabis Post-Harvest Rot

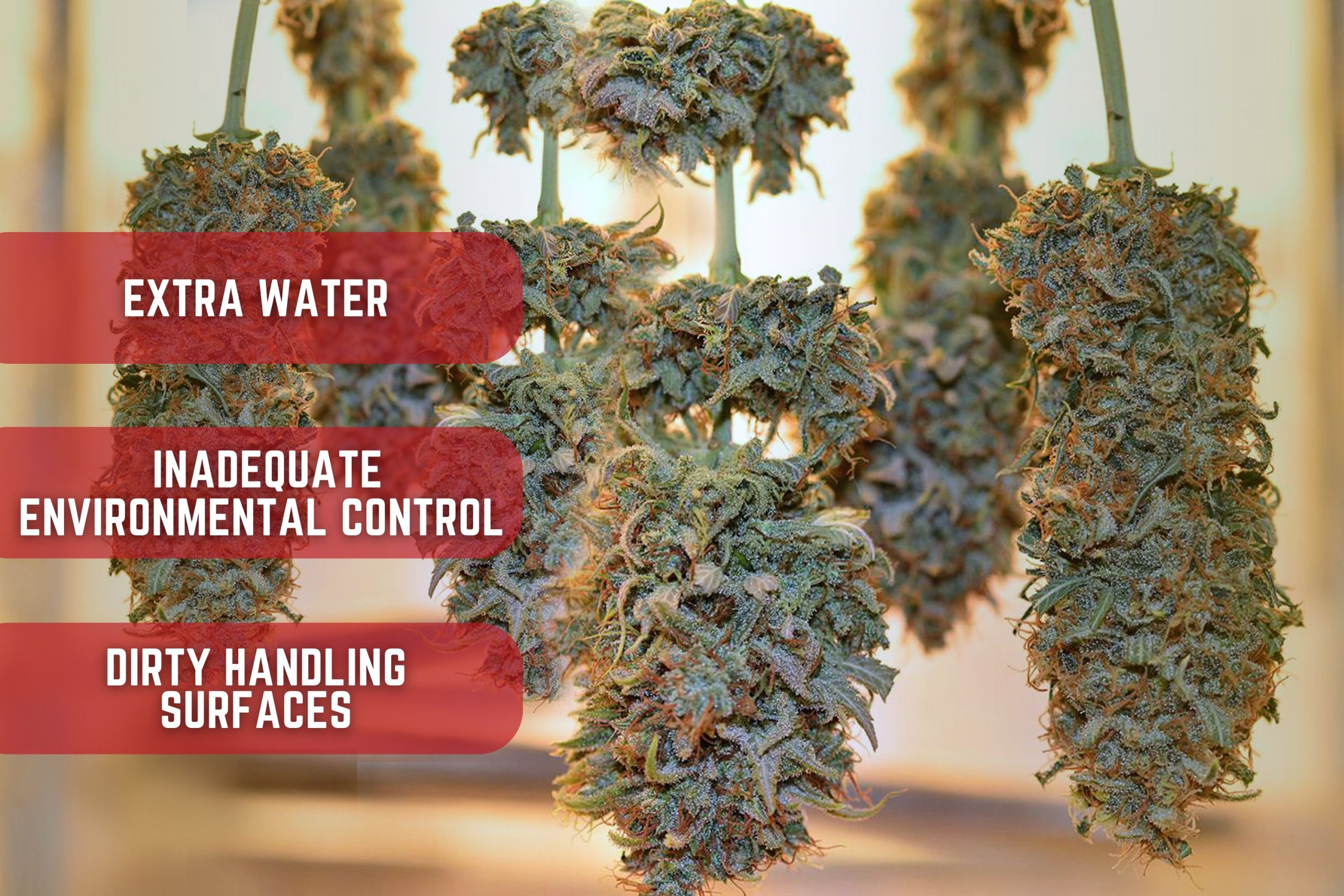

The extra water, inadequate environmental control, and dirty handling surfaces are mostly responsible for post-harvest spoiling. Once established, pathogenic bacteria, including Aspergillus spp. or Botrytis cinerea (rot of the buds), would rapidly break down the trichomes, terpenes, and cannabinoids, therefore rendering flowers either toxic or unsellable.

Apart from obvious eye-catching mold, microbiological deterioration can involve yeasts and bacteria affecting taste and chemical stability. Laboratory testing will commonly find these contaminants in regulated markets, causing batch rejection and financial losses. Therefore, for growers, the post-harvest interval has to be taken into account as a major control point where preventative actions equal the importance of farming techniques. Taking protective actions depends on the identification of weak points in the processing line.

Ideal Drying Room Conditions to Stopper Rot

Prevention of rot depends on a perfect drying environment. Our advised guidelines for maintaining cannabis buds in this sensitive state are:

- Maintaining between 60–68°F (15–20°C) slows down bacterial activities without compromising terpenes.

- Maintaining a relative humidity (RH) level between 50 and 55% will help to guarantee slow moisture elimination free from desiccation.

- Using oscillating fans positioned beneath and around (but not against) drying racks provides a continual mild flow of air to avoid microclimates.

- Let the room be dark to help stop cannabis from breaking down from light exposure.

The drying room has to be sealed and insulated to prevent outside moisture or pollutants. HEPA and carbon filters should be included in HVAC systems to lower airborne particles and bacterial spores. Especially in high-harvest-volume rooms, hanging branch or tray location should also be altered from time to time to provide for even drying.

Curing with Care: Airtight Storage with Controlled Venting

Cannabis moves to the curing phase when extra moisture in buds balances out, once it has dried. One of the second crucial points for rot growth is curing.

- Use stainless steel containers with tight seals or food-grade glass jars.

- Over the first two to three weeks, have containers open a few times a day for ten to fifteen minutes to vent extra humidity.

- Add 55–62% Boveda or Integra Boost packets to help stabilize internal humidity.

- Using small hygrometers in every container will help keep the RH within the safety range.

Successful curing also depends on the initial moisture content of buds—ideally 10–12% at introduction into jars. High residual moisture will cause internal RH to rise sharply, which will create favorable conditions for mold growth. Additionally is advised to keep curing jars in a dark, cold storage chamber that should ideally be maintained at 60–65°F (15–18°C), because high temperatures can promote microbial activity and degrade fragrant terpenes.

Sanitation Guidelines for Processing Post-Harvest

Of great importance is clean surroundings. Spores brought in by gloves, shears, or contaminated work surfaces will cause extensive rot.

- Every 30 minutes, sanitize tools, equipment, and receptacles with 70% isopropyl alcohol.

- When cutting sticky or mold-prone buds, replace nitrile gloves every 30 to 60 minutes.

- In between batches, clean tables, drying racks, and trimming tools are used with hydrogen peroxide or a quaternary ammonium compound.

- Use lab coats or throw away overalls to guard against outside contamination.

A consideration is also air disinfection. One can set UVC air cleaning equipment to eradicate airborne germs. In shared facilities, the use of footwear sanitation stations and HEPA-filtered clean rooms significantly reduces the risk of contamination. To prevent contamination at every post-harvest step, all these elements should be included in a more general Hazard Analysis and Critical Control Points (HACCP) strategy.

Mechanical vs Hand Trimming: Safety and Factors to Consider

Without enough trimming, the heavy blossoms can decay post-harvest. Although mechanical trimmers are very useful, they also present several hazards.

- Hand Trimming: Allows for detailed observation of every bud, enabling the detection of the first indications of mold. This method avoids mechanical pressure that bruises or tears the buds.

- Risks from Machine Trimming: Pathogens can find a reservoir in residue left over by cutting equipment. These need to be thrown out following every use.

- Best Practice: Have a cleaning plan between each change of strain and after shift, where trimmers prefer the Twister T4 or T6 use.

Another issue is wet trimming—before drying—versus dry trimming—after drying. Wet pruning exposes buds to a larger surface area of water and can cause increased cross-contamination in cases of inadequate equipment cleaning. Although it takes more time, dry trimming results in less microbial contamination and is easier to manage.

Systems of Environmental Monitoring and Alert Protocols

Real-time monitoring and autonomy give active defense against decaying conditions.

- Install sensors for temperature and humidity at several room heights to sense stratification.

- Data logging allows one to record environmental patterns to identify dangerous deviations in time.

- Set up RH spikes or temperature lows outside of a 5% variation.

- Provide standby dehumidifiers, fans, and HVAC systems for ongoing operation even with equipment breakdown.

To provide predictive analytics, intelligent controllers can also include environmental data ranging from room to room, drying, curing, and pruning. They provide data-driven SOPs, help to lower human error, and assist in maximizing harvest timing. GrowLink or TrolMaster systems let growers monitor conditions from afar and enable real-time automatic modifications by integrating with another system.

Packaging to Limit Contamination and Sequester Freshness

Poor packaging can hasten deterioration and bring air and moisture back in.

- Store for long periods beneath low-permeability Mylar bags.

- Closing out air with heat sealers is simple. While it’s appropriate for volume, vacuum sealing can shatter delicate blossoms.

- Oxygen scavengers help to slow down oxidative deterioration when employed in large-scale commercial applications.

- To maintain quality control, record the date packaged, the RH reading, and the inspected status on every product.

Second, packaging has to reflect the kind of product. While kief or pre-rolls might benefit from glass or hard-shell packing that won’t crush, whole flowers call for air-permeable but secure wrapping. Final packaged goods have to be kept in a climate-controlled chamber with shelves that allow heat dispersion by airflow.

Post-Harvest SOP Compliance and Staff Training

Human mistakes can destroy quality even with perfect tools and surroundings. Training and SOPs are non-negotiables.

- Microbial Awareness: Teach employees about mold growth and how their actions compromise product safety.

- Create and routinely go over cleaning, equipment use, and inspections, and then follow them.

- Assign supervisory employees random spot checks and follow through on procedures.

Ongoing education should include hands-on seminars, certificates in process handling, and continuous evaluation. Furthermore, highly helpful in regulatory audits are version control, date-stamped compliance, and traceable batch auditing made possible by using an electronic SOP system (e.g., METRC integration or ERP software).

Visual Mold Inspection Methods Before Storage

Before either final storage or selling, carefully visually check

- Use white light; steer clear of grow lights with yellow tones. White LED inspection lights more easily highlight mold.

- Hand lenses or USB microscopes (60x–120x) enable the small mycelium development hidden from view with the naked eye to be revealed.

- Use touch for overly moist or waterlogged areas. Either soft or smelling of ammonia, dry mold will.

Every bit as vital as having the correct tools is staff training to identify early mold indications. Red flags are gray fluff, unusual-colored pistils, or a strong, sweet, but earthy smell. Local law requires suspicious buds to be quarantined and submitted to a quality control database to be examined or eliminated.

Final Thought: Protecting Profits with Precision

It’s not only about cleanliness; avoiding rot in cannabis after harvest is mostly about building an airtight system of controls spanning from drying room environment to long-term storage. We ensure that every harvested bloom retains its full therapeutic, aromatic, and financial value by tightly managing the environment, maintaining rigorous sanitation practices, selecting qualified staff, and conducting thorough inspections.

Post-harvest cannabis storage’s future rests in merging data, automation, and compliance into a simplified workflow. Treating every stage as a component of an integrated quality assurance strategy helps growers safeguard not just their product but also their brand image and regulatory reputation. We can accurately and attentively avoid post-harvest rot, which is the exception rather than a costly inevitability.